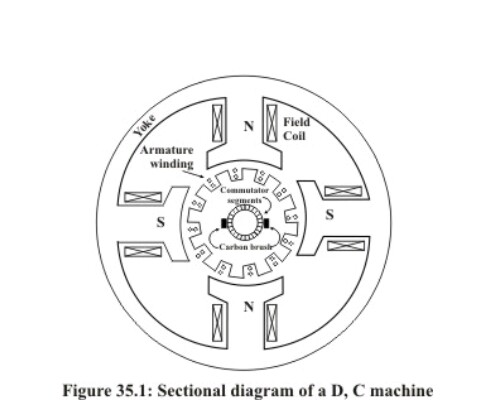

Constructional Features

Figure 35.1 shows a sectional view of a 4-pole D.C machine. The length of the machine is

perpendicular to the paper. Stator has got 4 numbers of projected poles with coils wound over it.

These coils may be connected in series in order that consecutive poles produce opposite

polarities (i.e., N-S-N-S) when excited from a source. Double layer lap or wave windings are

generally used for armature. Essentially all the armature coils are connected in series forming a

closed armature circuit. However as the coils are distributed, the resultant voltage acting in the

closed path is zero thereby ensuring no circulating current in the armature. The junctions of two

consecutive coils are terminated on to the commutator segments. Stationary carbon brushes are

placed physically under the center of the stator poles touching the rotating commutator segments.

Now let us examine how a D.C voltage is obtained across the brushes (armature

terminals). Let us fix our attention to a particular position in space. Whichever conductor is

present there right now, will have some definite induced voltage in it (dictated by e = blv). In

course of rotation of the armature newer conductors will occupy this position in space. No

matter which conductor comes to that particular position at any given point of time, it will have

same voltage induced in it. This is true for all the positions although the magnitude and polarity

of the voltages in different position may be different. The polarity of the voltage is opposite for

conductor positions under north or south pole. Remembering that all the conductors are

connected in series and brushes are suitably placed for obtaining maximum voltage, the

magnitude of the voltage across the brushes will remain constant.

To understand the action of the commutator segments and brushes clearly, let us refer to

the following figures (35.3 and 35.4) where a simple d.c machine working as generator are

shown with armature occupying various positions. Armature has got a single rectangular coil

with sides 1 and 2 shown in detail in figure (35.2). The two terminals 1 and 2 of the coil are

firmly joined to commutator segments C1 and C2 respectively. Commutator segments C1 and

C2, made of copper are insulated by mica insulation shown by lines between C1 and C2 and

rotate along with the armature.

No comments:

Post a Comment